📌 Quick Summary

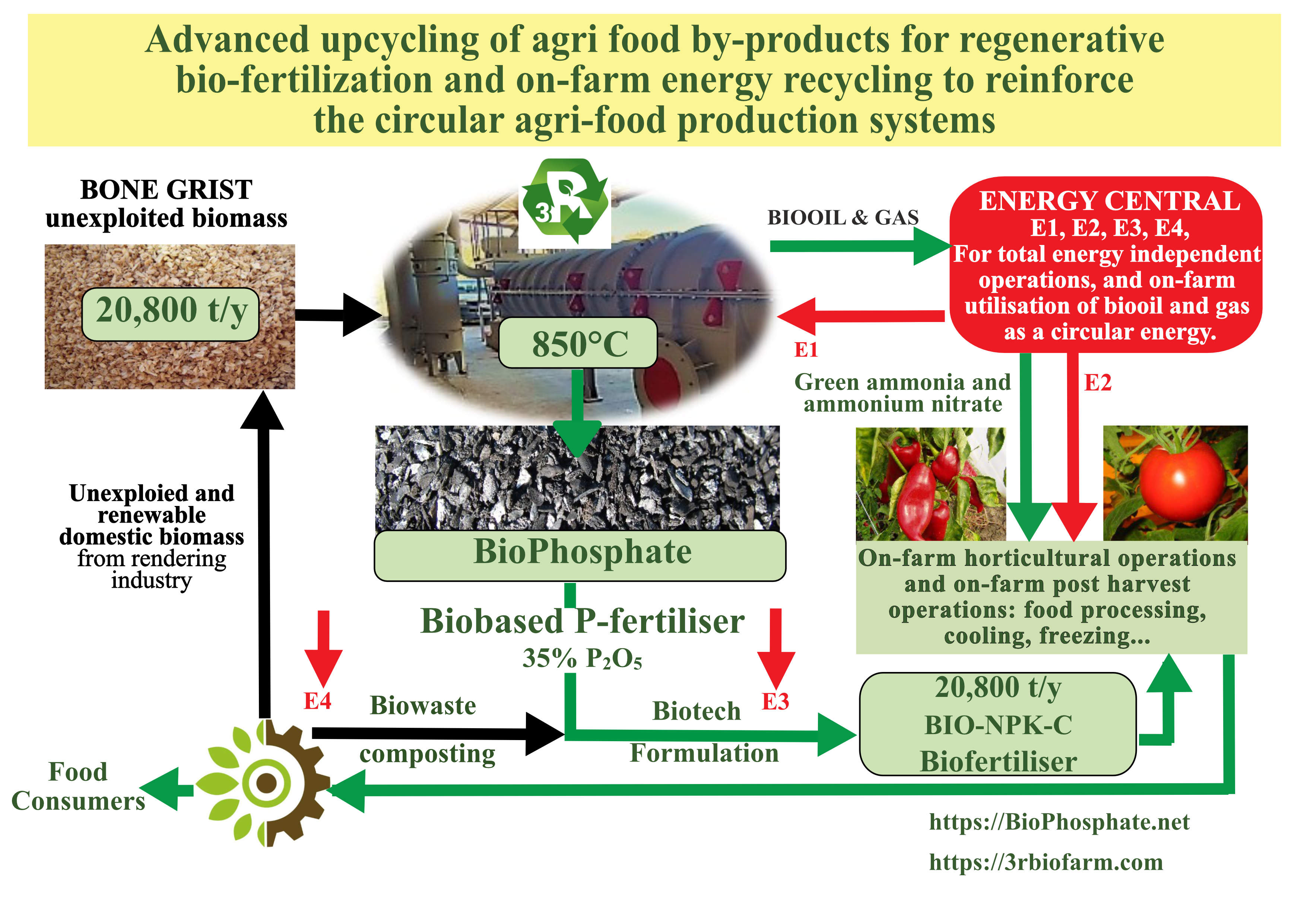

It supports agriculture, food processing, and energy use without external fuel. The 3R proprietary pyrolysis system is an auto-thermal, zero‑emission upcycling technology that transforms biomass into bio-oil and syngas, generating over 3 MWe/h of on-site renewable power (~24,000 MWe/year) without external fuel. This energy‑independent process supports sustainable agriculture, food processing, and energy needs.

Key Benefits:

- Energy self-sufficient pyrolysis producing surplus renewable power.

- Circular process: upcycles agri-food residues into fertilisers & bioenergy.

- On-site power for sustainable farm operations.

- Operational Resilience: Powers critical farm & post-harvest operations (greenhouses, cooling/freezing, fertiliser formulation) through clean, local energy.

- Business value: Delivers cost savings, ensures environmental compliance, and provides reliable renewable power for major agri-food operations.

This summary provides a concise overview of 3R integrated energy recycling system. The detailed sections below offer in‑depth insights into the 3R proprietary pyrolysis technology, its role in renewable energy recycling, and the economic and environmental benefits for investors, partners, and stakeholders.

Energy-Independent Innovation for the Circular Agri-Food Economy

3R Pyrolysis is a next-generation, zero-emission and energy-independent upcycling technology engineered to transform unexploited biomass into high-value, sustainable products. Designed to support the transition to circular agriculture, this technology ensures that all material streams are reused, upcycled, and converted into green energy and bio-based inputs.

This auto-thermal technology requires no external energy input and generates surplus green electricity, delivering more than 3 MWe/h (over 24,000 MWe annually) — a powerful step toward climate-neutral agri-food systems.

Key Benefits for Investors & Agribusinesses:

- Auto-Thermal Process – No external energy input needed, enabling energy-positive operations.

- 24,000 MWe/year surplus – Generated through on-site conversion of bio-oil and syngas, offering grid-free power independence.

- Full Circular Integration – All by-products are reinvested into the agri-food chain, reducing costs and emissions.

- High-Value Outputs:

- Bio-Oil: Renewable liquid fuel used for energy or green ammonia production.

- Syngas: Clean, on-site energy for farming operations.

- ABC BioPhosphate: Premium, phosphorus-rich biofertiliser replacing imported, chemically intensive alternatives.

Powering the Future of Farming

The bio-oil and syngas generated through the 3R system directly power critical on-farm activities:

- Self-sustaining operation of the 3R Pyrolysis Unit, producing BioPhosphate fertilisers with no fossil fuel dependency

- BIO-NPK-C formulation of the ABC BioPhosphate, including microbial enrichment and composting

- Horticultural energy needs, including sowing, greenhouse management, fertiliser application, and harvesting

- Post-harvest food processing, cooling, freezing, lyophilisation (freeze-drying), and storage

The 3R technology delivers an investor-ready solution for sustainable agriculture, enabling long-term energy security, cost efficiency, and environmental compliance. The integration of renewable energy recycling within on-farm operations not only guarantees environmental compliance but also provides reliable, on-site power generation. This approach supports sustainable agricultural practices and aligns with the growing demand for circular economy solutions in the agri-food sector.